Temporary/Portable Spill Containment Berm

Portable Berms are manufactured for the safe secondary containment of petrochemicals (oil, diesel, petrol) in drums, bags or bladder tanks.

All Berms are supplied packed in a plywood case, ready for dispatch worldwide, and include all the necessary tools, instruction manuals, spares and repair kit.

- Suitable for all climates.

- Suitable for all petrochemicals.

- Erected by 3 people within 1 hour.

- Re-useable at different locations.

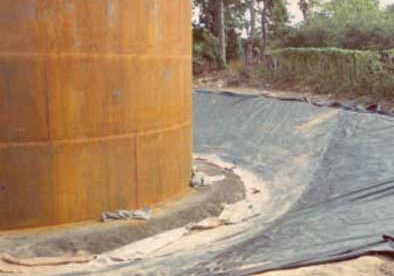

Berm Frame The common feature of the portable Berms is the steel framework which forms a module 1.5m wide by 0.3m high galvanised steel pipe and cast aluminium fittings. Each fitting is locked into position by a hexagon socket screw tightened by an allen key (provided).

Berm Material The berm’s geomembrane liner is fabricated from 1.00mm thick nylon reinforced Elvaloy.

- Tensile strength 265 dan/scm.

- Puncture resistance 267 dan.

- Hydrostatic resistance 4.1 MPa.

The material is resistant to all petrochemicals and a wide range of acids and alkalis.

Packing All Berms are packed in plywood cases ready for export.

Portable Berm Sizes and Capacities Berms are manufactured to meet customer requirements so can be produced in any size.